Products product definition and selection of ladder type cable tray

1, the product definition

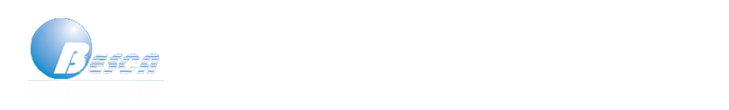

Ladder type cable tray

Cable tray when laid horizontally, should be according to the load curve select the optimum span of support span is generally 1.5~3.0M. When laid vertically, fixed spacing should not be greater than 2m.

Cable bridge (cable tray) is composed of pallets or ladder of straight line segments, siphon, components, and arm (arm-bracket), hangers, etc constitute the rigid structure of the cable system with close support in full.

2, product selection

1) cable trays, trunking and hanger for use in corrosive environments, rigid material that should be corrosion-resistant, or take measures to prevent corrosion, anti-corrosion treatment should meet the requirements engineering environment and durability.

2) within the cable tray in the fire sector, can be added in the cable ladder racks, trays with fire-resistant or flame retardant properties of plates, and other material enclosed or semi-enclosed structure, and take in the tray and brush fire protection coating on the surface of support and hanger measures such as its resistance should meet the requirements of relevant national norms or standards.

3) in the engineering of high fire place is not allowed to use aluminum cable tray.

4) cable ladder frame width and height of the selection, the fill rate requirements, cable ladder, fill rates in the General case, 40%~50% power cables, control cables 50%~70% and 10%~25% engineering margin should be reserved.

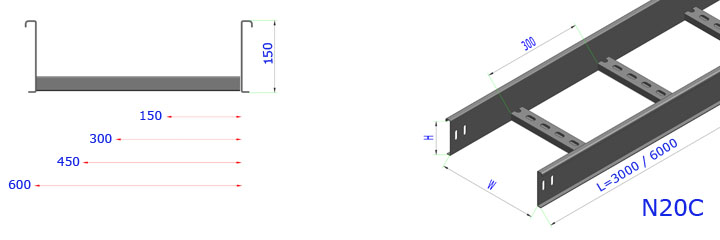

FRP Cable Ladder

5) when selecting a cable ladder load, cable tray uniform load should not exceed the selected cable tray load rated load if cable tray supports and hangers of the actual span is not equal to 2m, then the work load should meet the requirements.

6) and hangers in various components meet the conditions of the corresponding load, its size and tray, ladder straight, curved series of matches.

7) in select cable trays siphon or cited, and cited the next device, shall be not less than minimum bending radius of the cable within the cable tray. 8) for spans greater than 6m of steel cable tray and span greater than 2m or hosting request is greater than the load rating d aluminum cable tray, according to project conditions for strength, rigidity and stability calculations or experiments.

Steel Cable Ladder

9) sets of cable tray in the same highly parallel laying, between adjacent cable trays should be considered maintenance, overhaul distance.

10) ladder frame width and height normal specification see CESC31:91 of the steel cable tray engineering design specifications of the 2nd. 2.2.

11) ladder frame width and height normal specification see CECS106:2000 of the technical specification for aluminum-alloy Cable Tray 3rd. 1.2.

12) ladder frame and aluminum tray, ladder through a single standard length can be 2, 3, 4, 6m.

13) steel cable tray surface anti-corrosion treatment see CECS31:91 steel cable tray engineering practice 3rd. 4.2.

14) aluminum Cable Tray surface anti-corrosion treatment see table CECS 106:2000 technical specification for aluminum-alloy Cable Tray 4th. 4.1.

Source: https://www.bescatray.com/